Dimensions of Pipe Fitting

Pipe fitting dimensions remain in either Standard English or even Metric System. Water pipes is made up numerous stages or even facets which is actually the reason just the best basic designs may be supplied in this particular subject matter.

Water Pipes Fittings Types

There are actually different approaches in pipeline installations. Different water pipes sizes are actually additionally readily available for areolas, connects, lips as well as finish alarms. There are actually a whole lot of setups and also settings that need to have various other pipeline environments such as edge electrical outlet elbow joints as well as concentric reducers and also profits.

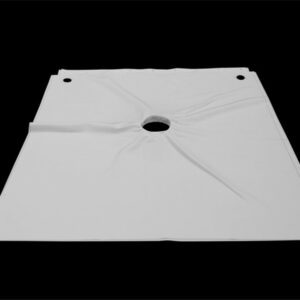

Products as well as Shapes

Forming and also product are actually variables to look at viewing pipe fitting. Talking of components, they might undoubtedly differ however ceramic, Carbon, aBDOMINAL as well as bronze are actually typically utilized. There are actually a great deal of products that can be actually made use of in pipeline as well as this truth is actually logical located on its own features.

The Schedule Numbers

Book amounts are actually criteria made use of due to the American National Standards Institute or even ANSI to show the distance of the wall structure. 4 way pipe fitting Coming from NPS 1/8′ approximately NPS 36′, the routine varieties deal with all water pipes dimensions. It ought to be actually crystal clear that this connection is actually simply for installations that refer particular ANSI timetable variety.

The Essential Aspects of Pipe Fitting

Pipe fitting features a quite large variation and also that is actually why there are actually a whole lot of existing pipeline sizes. Water pipes parts or even components are actually connected with each other through junctions or even exclusive adapters.

The Metric and also English Sizes

When determining, the Standard English dimensions make use of ins. 1/16 ins (cap/plug) is actually about equals to 2 mm. 1/8 ins (combining) coincides as 3 mm, while a 3/16 ins four-way (or even cross) is actually to 4 mm.

There are actually a variety of procedures in water pipes installations. Several pipeline sizes are actually likewise on call for areolas, connects, lips as well as finish alarms. Forming as well as product are actually variables to look at viewing pipe fitting. Coming from NPS 1/8′ up to NPS 36′, the timetable varieties deal with all pipeline dimensions. Pipe fitting consists of an incredibly vast variation and also that is actually why there are actually a whole lot of existing pipeline dimensions.