There are several manufacturers and suppliers of brick making machines in the USA.

Here are some examples of companies that offer brick making machines in the USA:

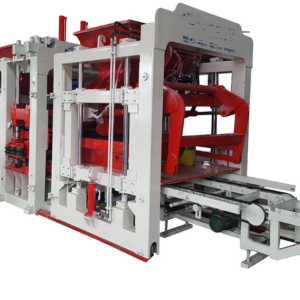

Besser Company: Besser Company is a manufacturer of concrete products equipment, including block, brick, and paver making machines. They offer a range of models designed for various production capacities and end product types.

Columbia Machine, Inc.: Columbia Machine is a global supplier of concrete products equipment, including block, brick, and paver making machines. They offer a range of models designed for various production capacities and end product types, as well as custom solutions.

Global Machine Market: Global Machine Market is a supplier of concrete products equipment, including block, brick, and paver making machines. They offer a range of models designed for various production capacities and end product types, as well as accessories and parts.

Hydraform USA: Hydraform USA is a distributor of Hydraform block, brick, and paver making machines. Hydraform machines are designed to produce interlocking blocks that do not require mortar and can be used in a variety of construction applications.

TIGER International, Inc.: TIGER International is a manufacturer of concrete products equipment, including block, brick, and paver making machines. China brick making machine usa They offer a range of models designed for various production capacities and end product types, as well as custom solutions.

When selecting a brick making machine in the USA, it is important to consider factors such as the manufacturer’s experience, product range, customer service, and after-sales support. A reputable manufacturer or supplier should be able to provide expert advice on selecting the right brick making machine for your specific application, as well as provide installation, training, and maintenance services to ensure the optimal performance of the equipment.

Maintaining a brick making machine is essential to ensure its optimal performance and longevity.

Here are some common maintenance requirements for brick making machines:

Lubrication: Regularly lubricate the moving parts of the machine, such as the bearings, chains, and gears. Use the manufacturer’s recommended lubricants and follow their recommended lubrication schedule.

Cleaning: Regularly clean the machine to remove any debris or buildup that may affect its performance. Use a soft brush or cloth to remove dirt and debris, and avoid using abrasive materials that may damage the machine’s surfaces.

Inspection: Regularly inspect the machine for any signs of wear or damage, such as cracks, worn-out parts, or loose bolts and nuts. Replace any damaged or worn-out parts immediately to prevent further damage or safety hazards.

Adjustment: Regularly adjust the machine’s settings, such as the pressure and speed, to ensure that it produces quality bricks. Follow the manufacturer’s recommended settings and adjust them as necessary based on the type and quality of the materials being used.

Training: Ensure that your staff is trained on the proper operation and maintenance of the brick making machine. Provide regular training and refresher courses to ensure that they are up-to-date on the latest maintenance requirements and best practices.

By following these maintenance requirements, you can prolong the life of your brick making machine and ensure that it produces high-quality bricks consistently. It is important to consult the manufacturer’s manual for specific maintenance recommendations and to contact them for any questions or concerns regarding maintenance or repair.